Micro DTi Series

Hybrid machine with 8 processes in one Single Machining Centre.

We've listened to you ...

We’re Excited to Deliver!

The next generation of the DT-110 is just around the corner, designed with your needs and feedback at its core. We’ve taken everything you loved about the original DT-110 and elevated it to a whole new level.

What to Expect?

The upcoming DT-110 will feature a more compact design while maintaining the accuracy and efficiency you expect, all at a very competitive price. It’s a blend of innovation and affordability, ensuring you get the most out of your investment without compromise.

Stay Tuned!

More details are coming soon. This is just the beginning of a new era in advanced machining technology, and we can’t wait to share it with you.

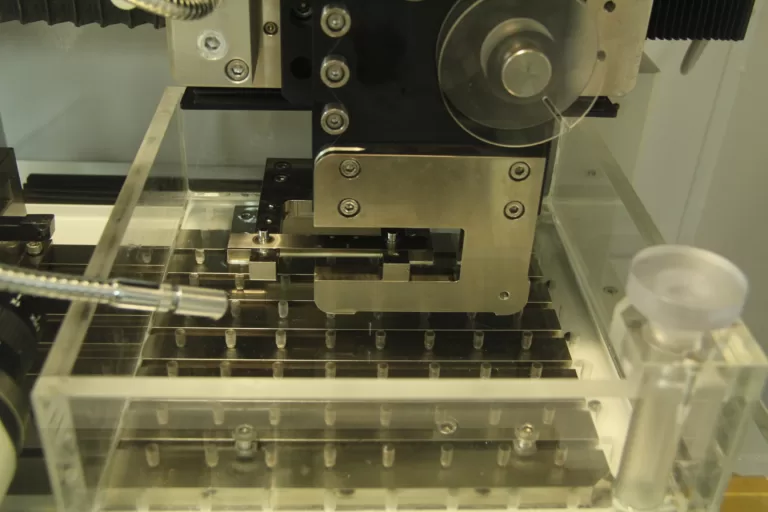

Hybrid μEDM Machine

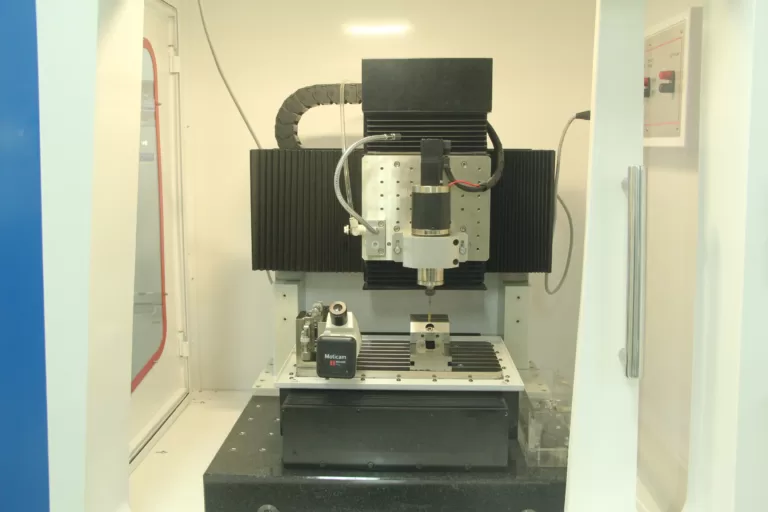

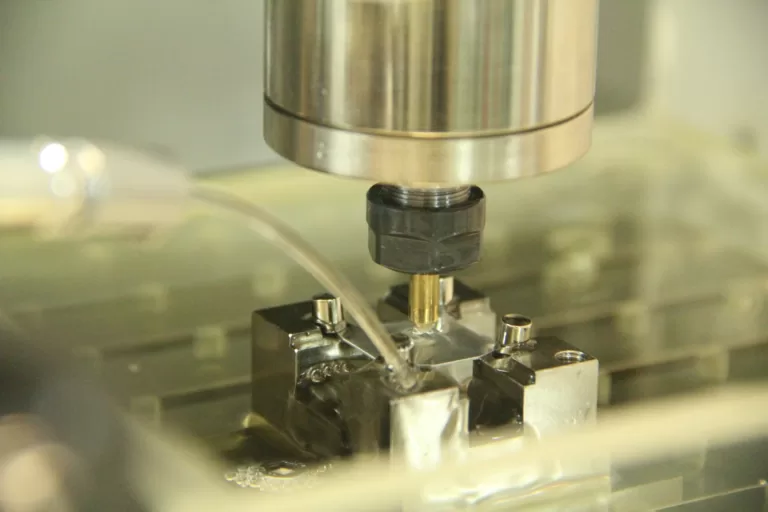

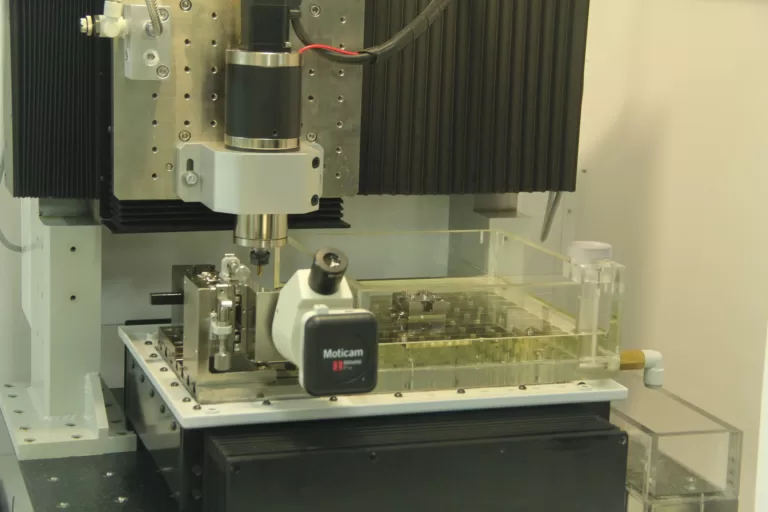

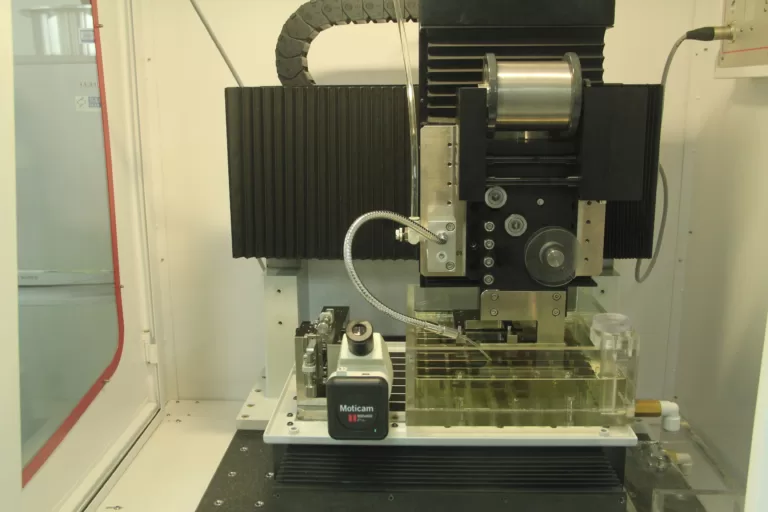

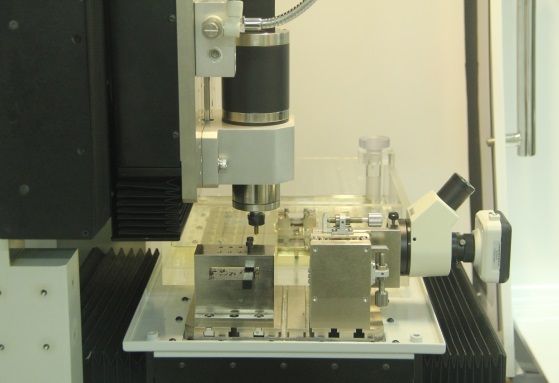

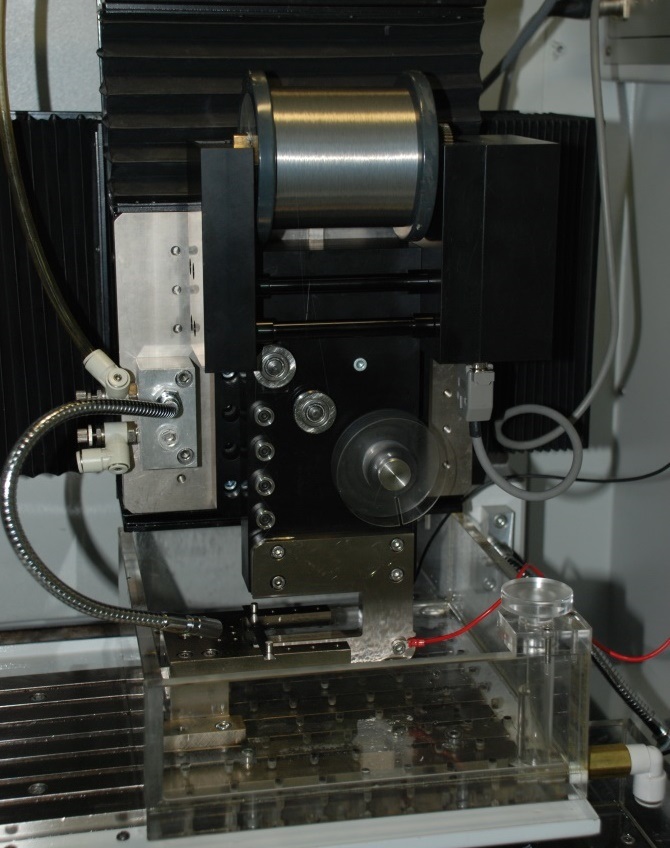

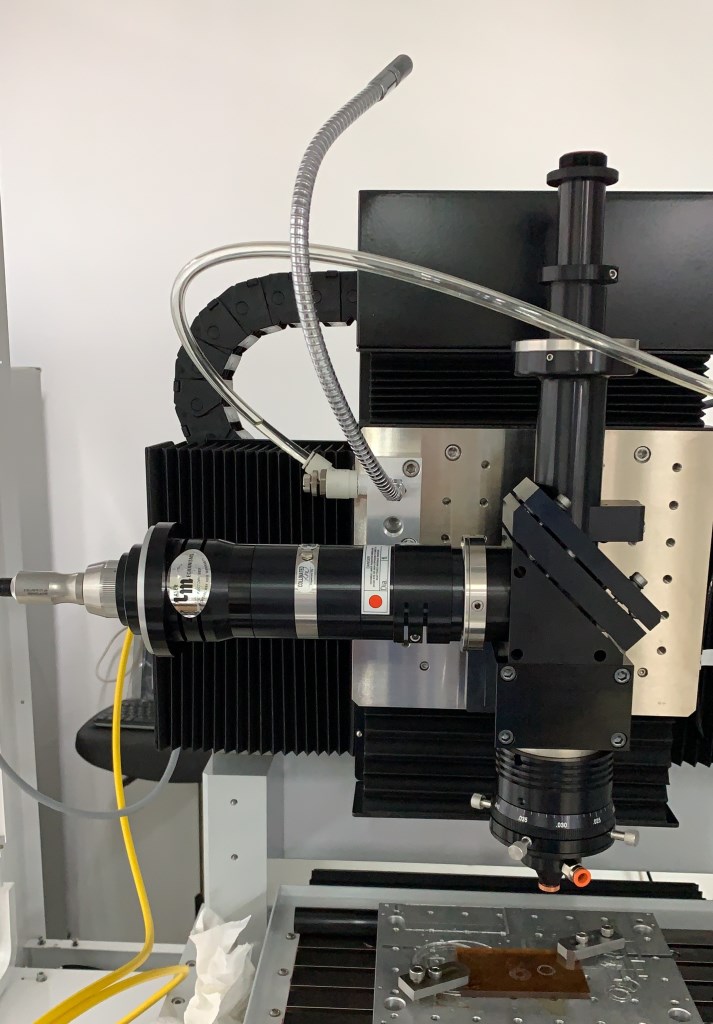

The DT-110i Hybrid μEDM machine has been engineered from day one to excel at micro-machining. Hybrid μEDM is the utilization of 2 or more processes, including EDM, on the same machine to achieve the highest levels of accuracy, precision and throughput.

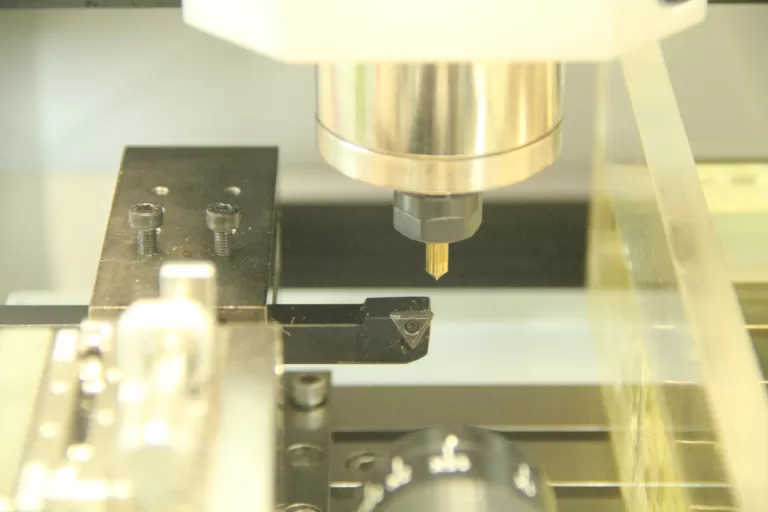

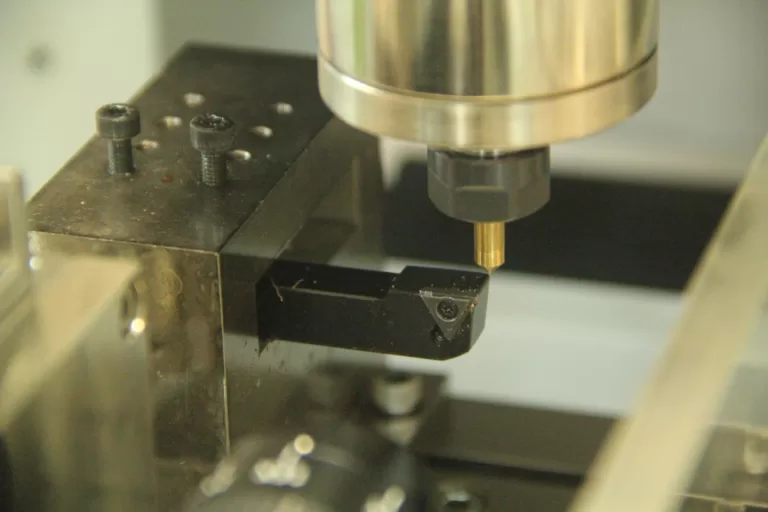

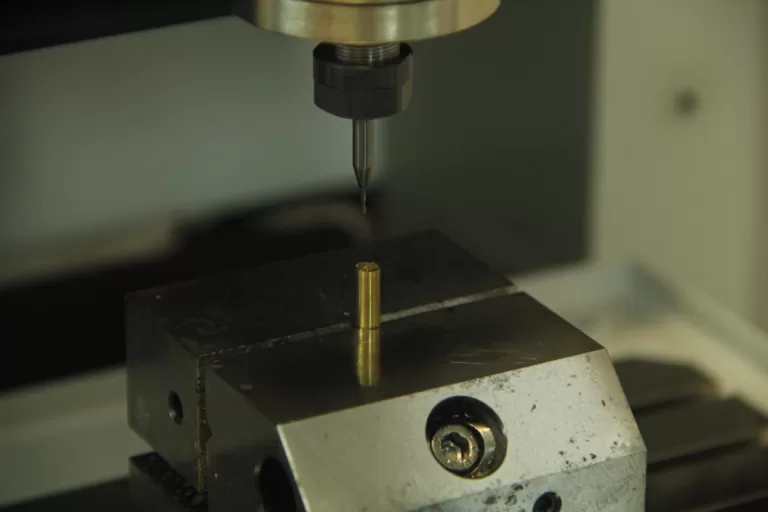

For example, with its patented hybrid μEDM technology, micro-sized electrodes can be fabricated directly on the DT-110i with pinpoint accuracy. This can be done by first turning the electrode and subsequent fine machining using wire electrical discharge grinding.

Combine the 2 processes make the machining 50 to 100 times faster! The possibilities of the DT-110i are endless.

General Features

- High stiffness gantry structure mounted on Natural granite table for high precision and damping characteristics

- Precision ball screw drive system with fine pitch lead screw

- High precision pre-loaded linear guide way with more than 350N/μm stiffness

- High resolution of 0.1μm optical scale based linear encoder for precise closed-loop feedback

- PC based CNC motion controller with 0.1 micrometer (100 nanometer) programming resolution

- Mikrotools in-house developed touch screen based graphic user interface (GUI) for an operator friendly machine operation

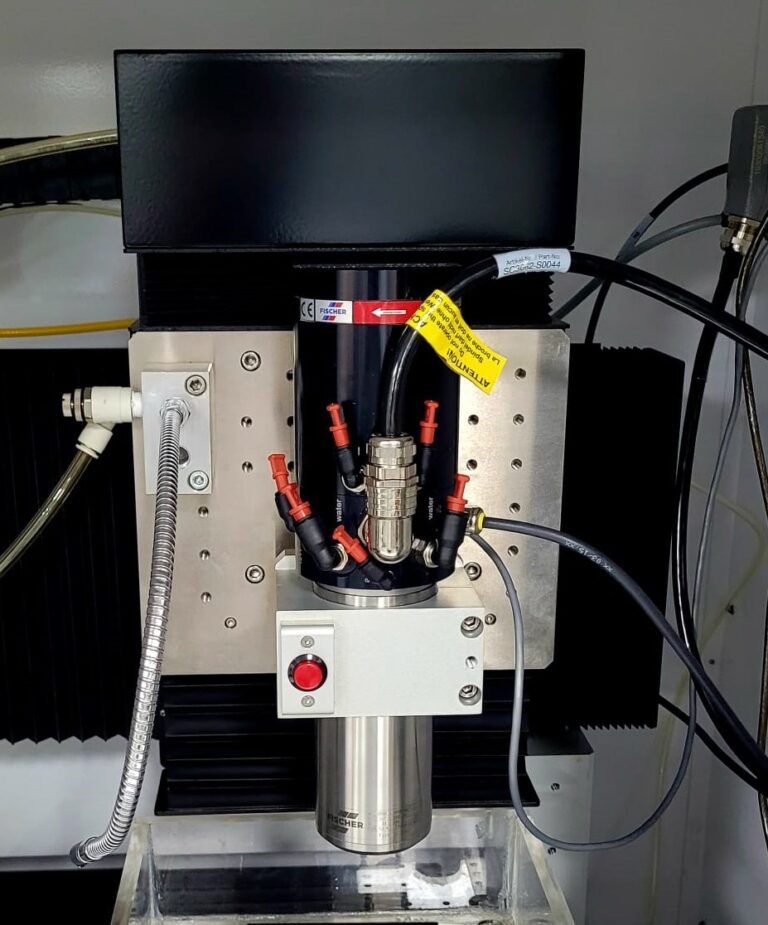

- Electrically isolated spindle to support traditional and nontraditional micro machining processes

- Travel: 200 mm (X axis) x 100 mm (Y axis) x 100 mm (Z axis)

- Compact floor footprint: 3 m X 2 m

Unleash the Full Capabilities

Electric Discharge Machining (EDM) based processes:

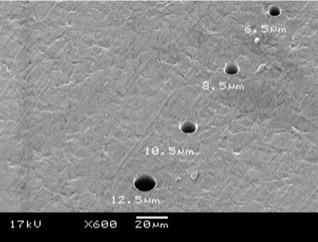

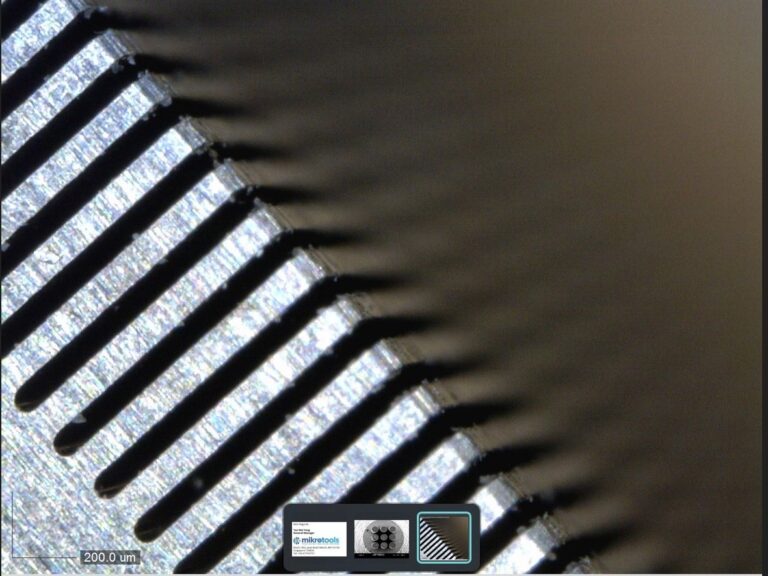

- Micro-EDM Slot Milling/Drilling – Precision micro-machining of metallic materials irrespective of their hardness

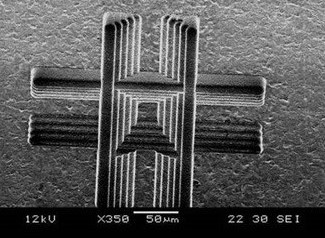

- Micro-Wire EDM – Precision profile cutting of metals and alloys

- Micro-Wire Electrical Discharge Grinding – Preparation of micron sized tools

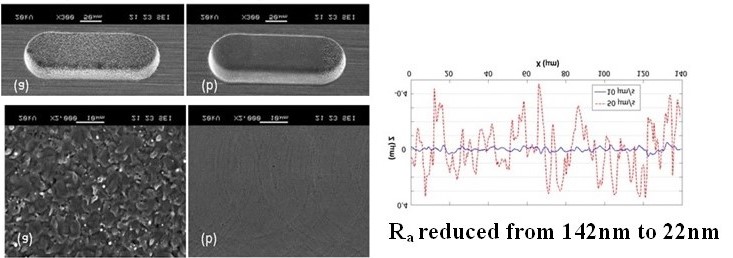

- Simultaneous EDM-ECM (SEDCM) – Exceptional Nano-finished surfaces

Laser Ablation processes:

- Micro-Laser Machining – Fine micro-slot cutting, surface texturing & engraving on metallic sheets

Traditional based processes:

- Micro-Turning – Fabrication of micro-shafts

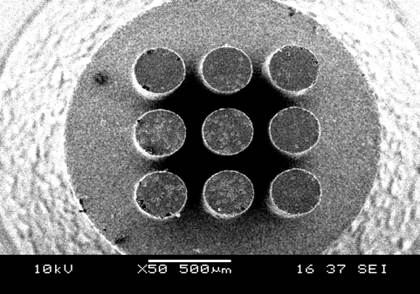

- Micro-Milling/ Drilling – Precision levelling of parts, micro-slot & holes fabrication.

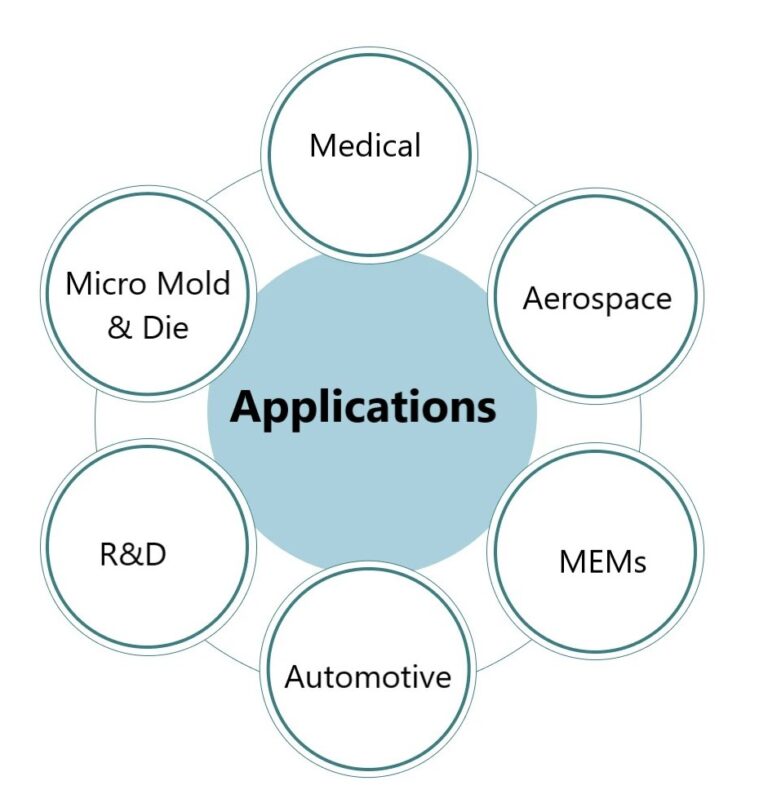

Applications