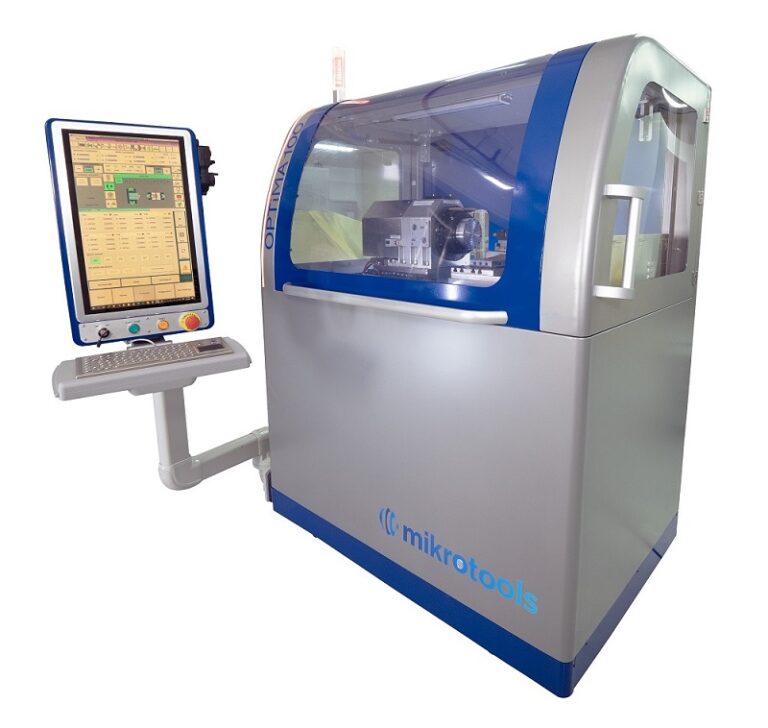

Optima Series

Diamond Turning Ultra-Precision Lathe

Optima Series - Ultra Precision

At Mikrotools, we offer tailored products to cater to the unique requirements of individual customer’s applications.

Based on the specific application (IOL, contact lens, mold inserts etc.) and workpiece materials consideration (Hard-to-cut materials like WC, Si, IR crystals, silicon-based ceramic, glass, quartz, ferrous-based metals, nickel-based superalloy, zirconium, polymers (PMMA, Polyesters) etc.) of the user, Mikrotools will customize the machine specification accordingly to meet the user’s application requirements technologically and economically.

General Features

- 2-axis “T” configuration slide-ways mounted on natural granite table with high precision and damping factor

- High precision linear hydrostatic guideway

- Ultra-high resolution of 8 pm linear optical encoder for high accuracy feedback system

- High precision AC linear motor drives with linear power amplifier units

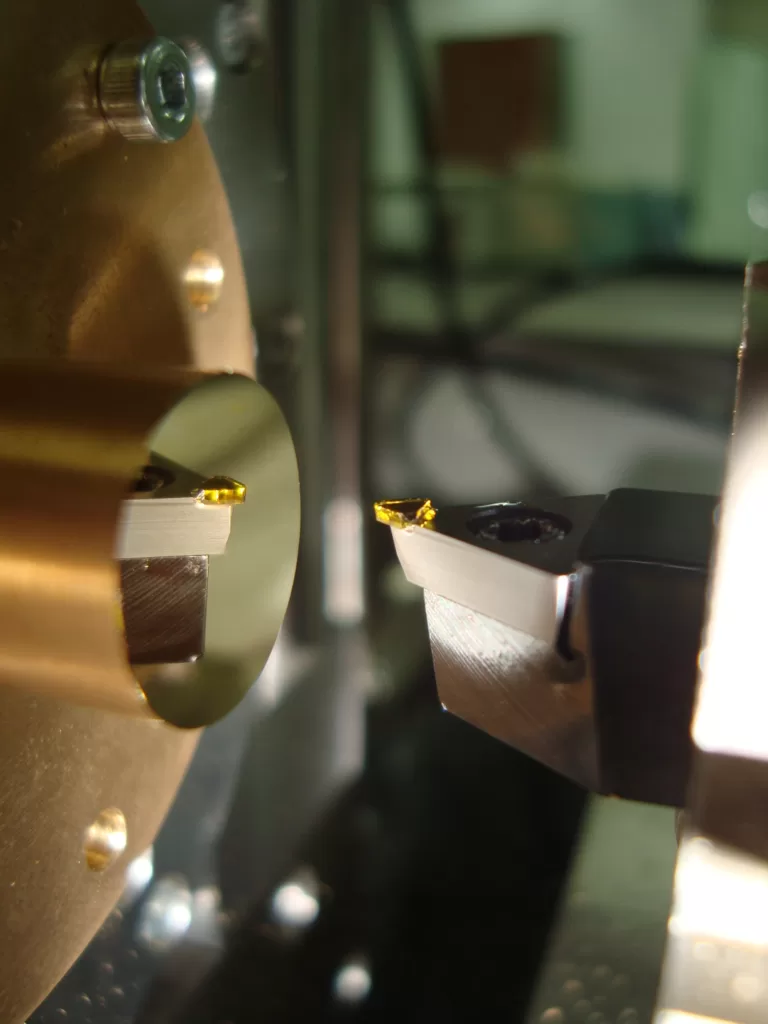

- Manufacturer calibrated and tested Aerostatic spindle with high resolution encoder system for ultra-precise rotary motion profiles

- Compatible with standard optics-based CAM software

- Multi-axis motion control system for synchronized motion control

- Customized Windows system with touch screen based Graphical User Interface (GUI) design

- Passive pneumatic vibration dampers for effective isolation to machine structure

- Optional Vacuum chuck system for quick mounting of workpiece

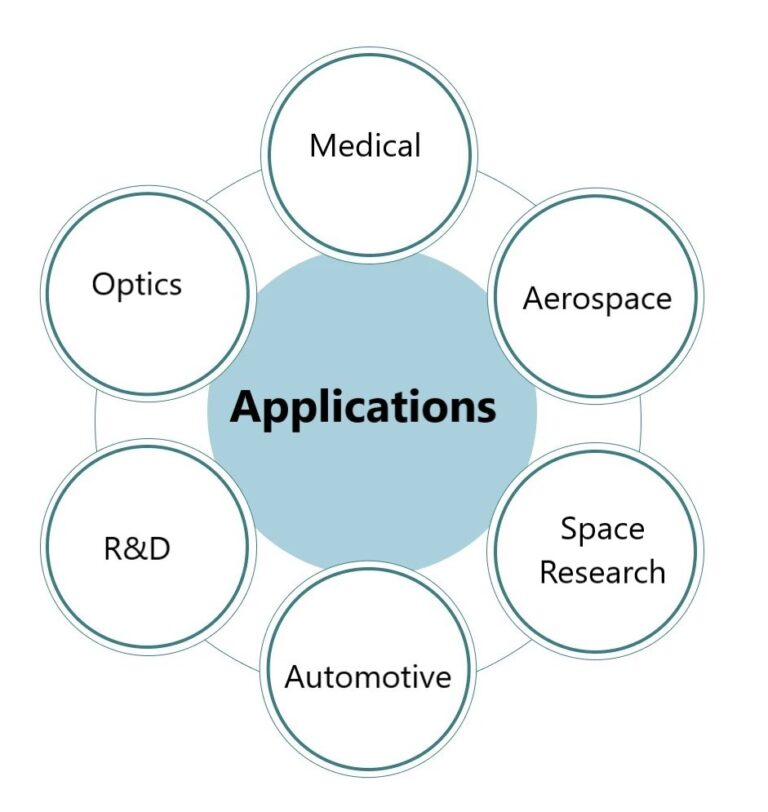

Applications